Dịch vụ

POSITIVE MATERIAL IDENTIFICATION (PMI)

Positive Material Identification (PMI) is widely used many idustries as the needs for metal alloy material verification is increasing. Special engineered materials are continuously being developed to better withstand the specific stresses and requirements for many specialized applications.

EDDY CURRENT TESTING (ET)

Eddy Current testing (ET) is used widely in industries for examining various properties of conductive materials. Among these, the detection of the in-service cracks in steel welds of crane pedestal and jacket of platforms are widely used during periodical maintenance inspections.

RADIOGRAPHIC TESTING (RT)

Radiographic testing (RT) is widely used to detect the discontinuities in materials and welds. This method is most sensitive to volumetric discontinuities. It is currently used as one of the main NDT methods to provide QAQC reliability for new fabrications in oil & gas, power generation, chemical and ship building industries.

DYE PENETRANT TESTING (PT)

Dye Penetrant testing (PT) is used to detect the surface breaking discontinuities in non-porous materials. These discontinuities may be relating to new fabrication processes or in-service of objects. The typical discontinuities can be found are cracks, voids, porosity, inclusions, seams, laps and fatigue cracks.

MAGNETIC PARTICLE TESTING (MT)

Magnetic particle testing (MT) is used to detect the surface breaking and slightly subsurface discontinuities in ferromagnetic materials. These discontinuities may be relating to new fabrication processes or in-service of objects. The typical discontinuities can be found are cracks, voids, porosity, inclusions, seams, laps and fatigue cracks.Our inspectors are experienced, well trained and qualified in accordance with worldwide recognized standards such as PCN, CSWIP, ASNT and SNT-TC-1A.

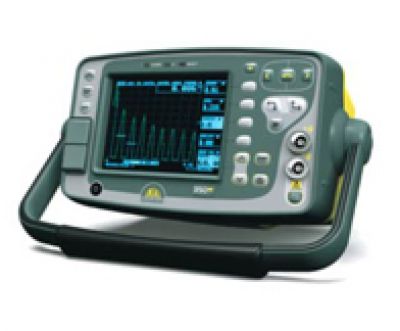

ULTRASONIC FLAW DETECTION (UT)

Ultrasonic testing is a useful mean for assessing the integrity of the welds in T, Y, K configurations and the heavy wall thickness welds during fabrication and in-service inspection. Our UT inspectors are well trained and qualified in accordance with worldwide recognized standards such as PCN, CSWIP, ASNT and SNT-TC-1A for categories of weld configurations from butt weld in plates, nozzle welds to tubular variable configuration node weld