Microstructure evaluation in conjunction with metallurgical template replication is a non-destructive inspection technique used to evaluate the microstructure of materials in use at the plant in order to predict the risk of damage of components, parts, industrial equipment.

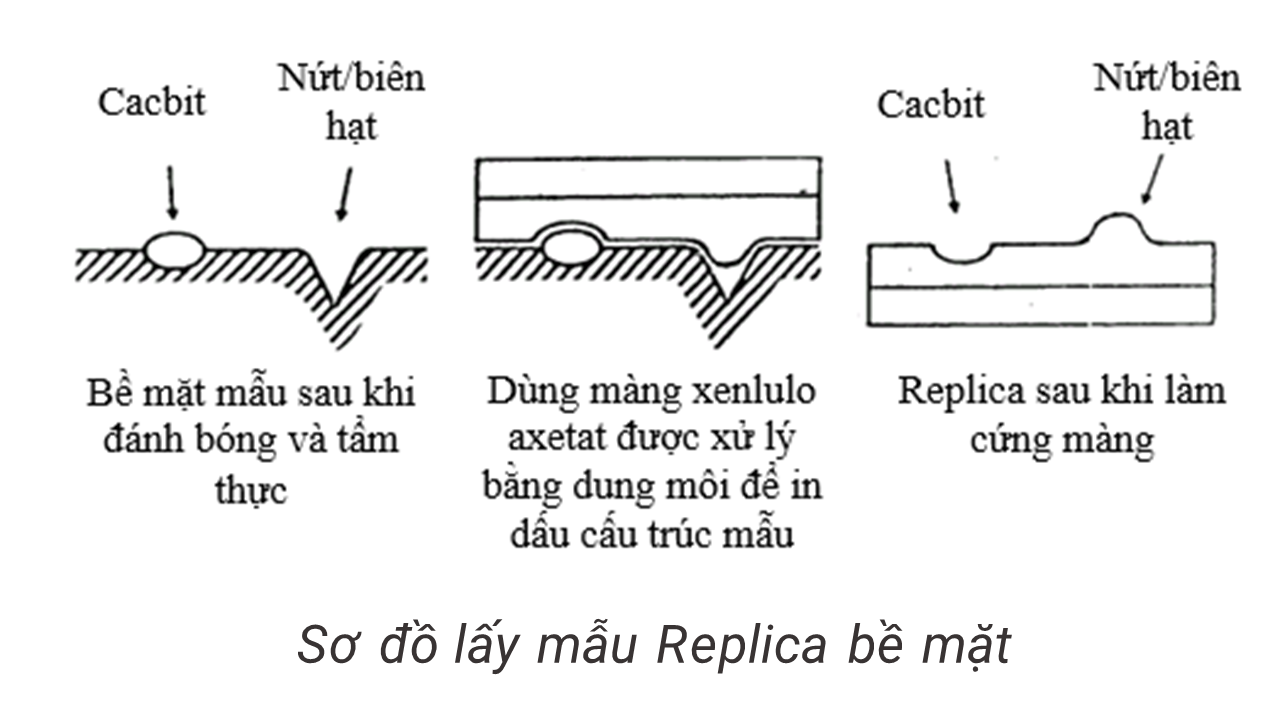

The basic steps of the microstructure evaluation technique in conjunction with the metallurgical template replication process:

· Surface polishing, using grinding paper from 200 grit to 1200 grit in combination with diamond powder ranging in size from 0.5-2um

· Real impregnation with a real impregnation solution (e.g., 2-4% Nital for carbon and low alloy steels)

· Sampling of the actual impregnated surface structure, using a solvent-softened cellulose acetate film.

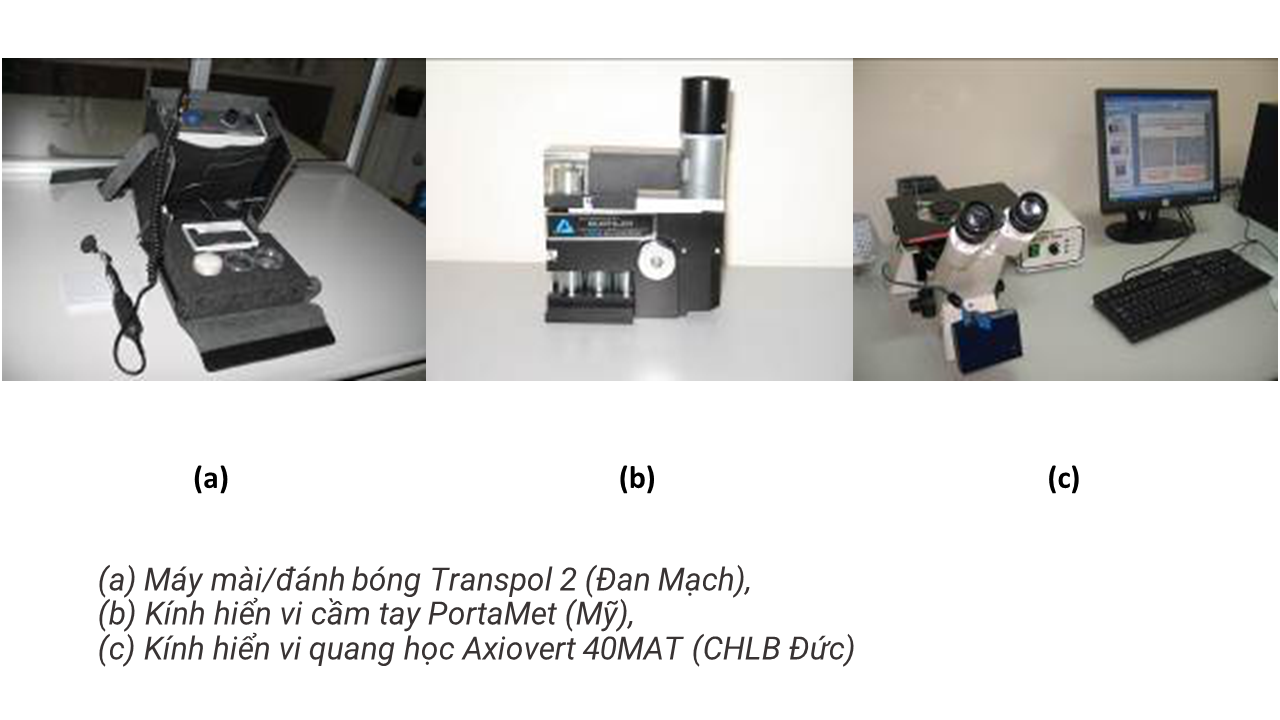

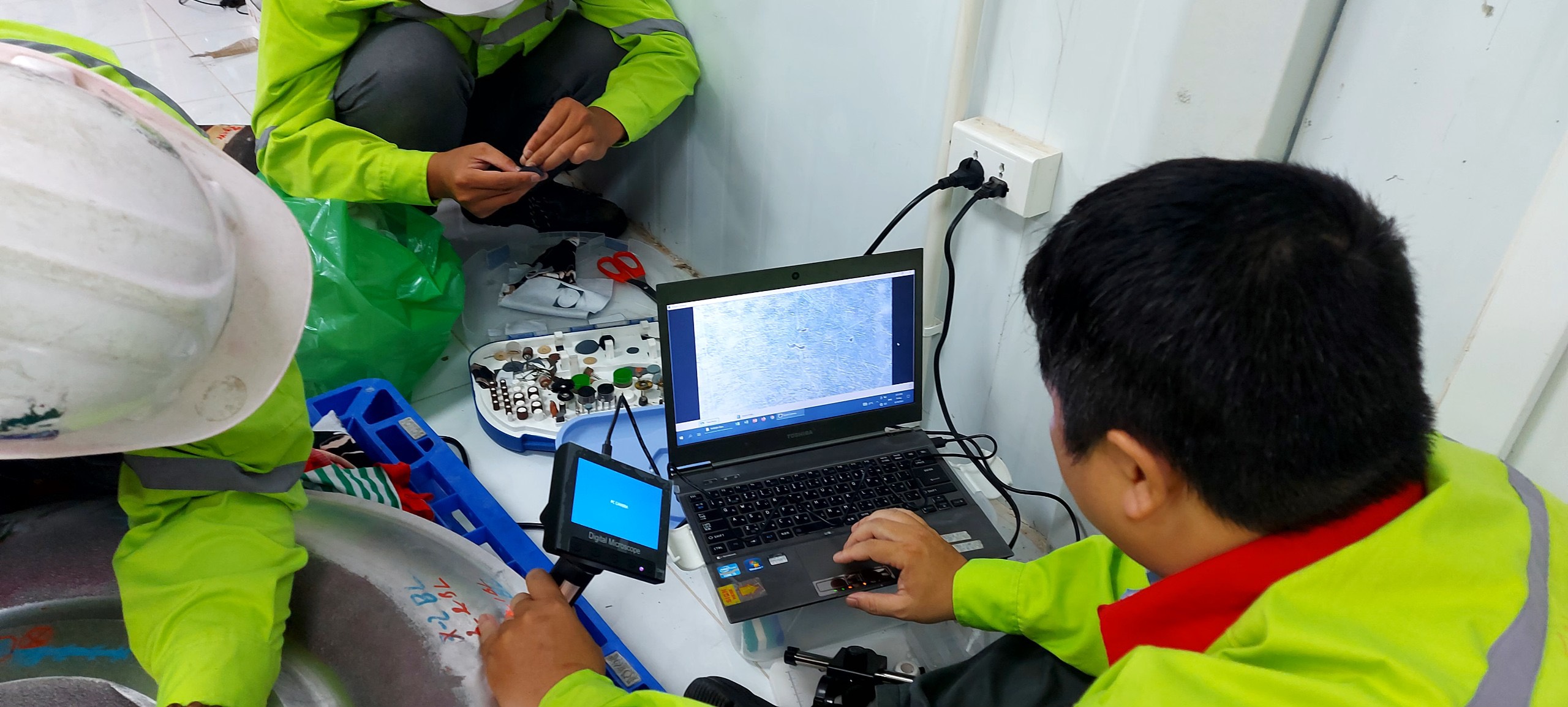

· The printed film sample of the structure is removed from the metal surface, preliminarily examined in situ by a handheld microscope and numbered/denoted the sample, preserved and taken to the laboratory.

· The replica film is coated with a layer of metal (Pt, Au, Ag...) to increase contrast.

· Study/imaging of structural sample film on optical microscopes or scanning electron microscopy (SEM).

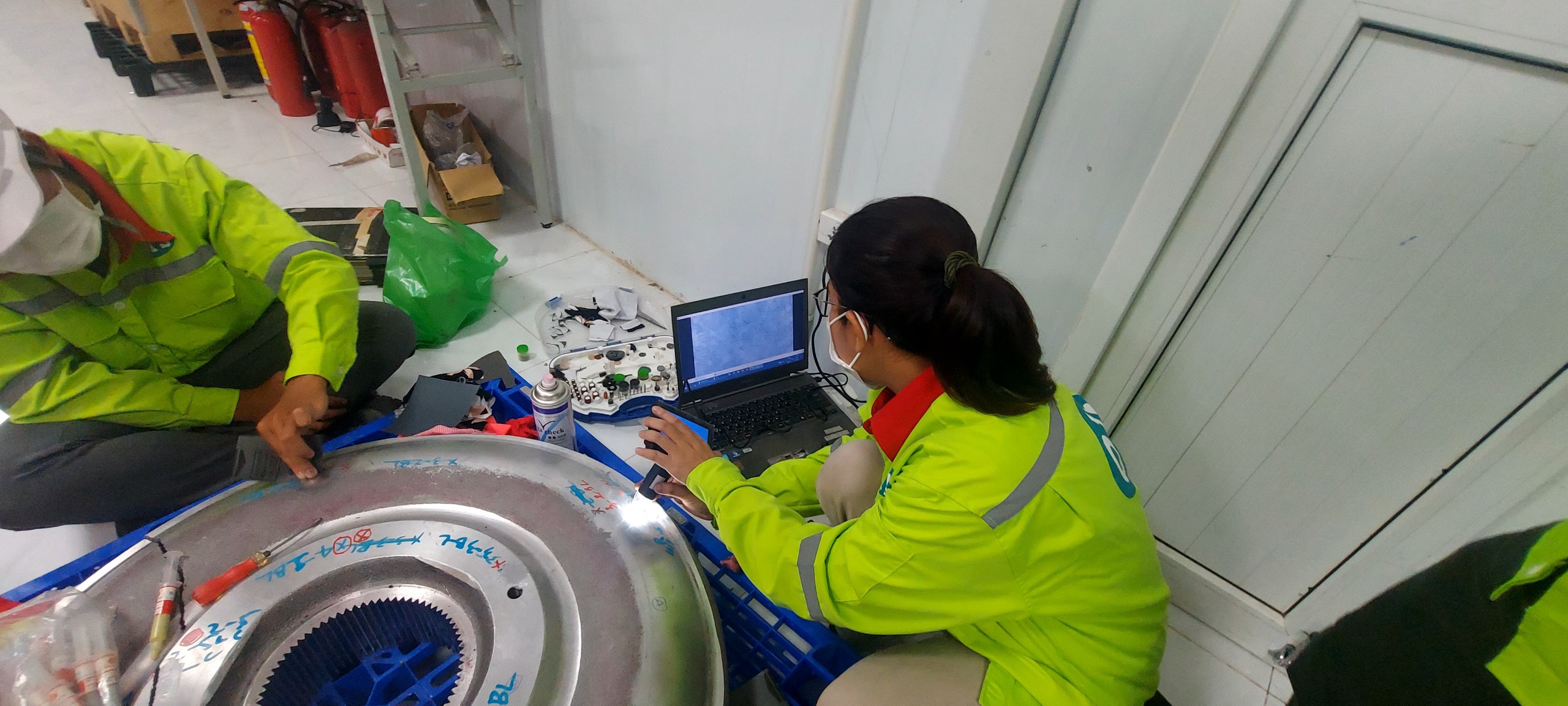

The advantage of the microstructure evaluation method combined with the metallurgical template copying process is that it can be performed in the field, directly on the components and equipment in the factory production line, samples are not allowed, or the components are too large to be brought to the laboratory and can perform this inspection process even when the plant is in operation. This method is an important tool for making the decision to run, repair or replace, ensuring plant operation safety.

A variety of information can be obtained using this method, including:

· Determine the material family/type (cast iron, austenitic stainless steel, carbon steel).

· Detection of other microstructure changes that occur at high temperatures due to environmental exposure in boilers, pressure vessels, pipes and other parts.

· Determine the presence and phase of runoff damage by observing common metallurgical features including: sphericalization, formation of isolated and directed cavities, microcrack and macrocrack.

· Analysis of heat treatment results in materials when fabricating and heat treatment after welding.

· Evaluation and classification of surface indicators (pitting, slag, layer separation, cracks, seams).

· Ensure equipment and materials purchased in accordance with technical requirements.

· Classification of details by spherical cast iron material in RMB.

· Determine the limits of damaged components that need to be replaced.

Some pictures of Replica and Microstructure at construction site

The microstructure evaluation technique combined with the metallurgical template replication process is an important tool with high efficiency, has been developed and widely applied around the world, however, in Vietnam, this method has only been applied in about a decade and there are still not many providers of this service.

With the goal of sustainable development, diversifying products and services, optimizing technology to lead all trends, Q.I.S with experience has pioneered and become the first unit in Vietnam to successfully implement and apply this method to more than hundreds of factories in the fields of thermal industry. electricity, hydropower, oil refining, chemicals, fertilizers ... This advanced technique has helped factories save many billions of VND by reducing the cost of hiring experts from abroad, shortening maintenance time due to using domestic services, soon putting equipment back into operation every time there is a problem and ensuring the safety of production labor.

QIS has been highly appreciated by customers for its capacity as well as working results, along with a team of highly selected leading engineers and doctors, a team of skilled technicians with many years of experience, flexible management systems, machines, the most advanced equipment has contributed to the reliability and satisfaction of customers for the QIS's brand.