Post weld heat treatment (PWHT) is a process applied to welded joints and high strength base steels. PWHT is performed after welding for the purpose of reducing residual stress, controlling the stiffness of the joint area and improving it’s longevity with processing temperatures up to 900 degrees C. If PWHT is not performed after welding with some high strength steels, the residual stresses associated with the stress during operation may exceed the ultimate stress of the material. This leads to damage to the weld, causing the risk of cracking or increased susceptibility to cracking. When performing heating or PWHT after welding, it is important that the operator knows the exact specifications, the metal’s properties as well as the steps to be taken, otherwise it may cause serious effects on product quality.

Heating process before welding

Joints before welding must be heated for the following reasons:

- Remove steam from the area to be welded. The heating temperature is usually just higher than the water’s boiling temperature, removing water from the joint helps to eliminate porosity, brittleness, cracking of welds caused by hydrogen generated during water decomposition by high temperatures when welding.

- Reduce the temperature difference between the welding heat source and the solder. All arc welding processes use a welding heat source much larger than the solder’s temperature. This difference causes serious errors such as cracking of the weld for high hardness metals and not ensure the weld’s mechanical properties compare to the weld metal’s one.

We can heat the weld using gas burners, electric heating, electromagnetic heating or using a furnace. The heating process must ensure heating of the entire welding area, heating the entire thickness of the solder.

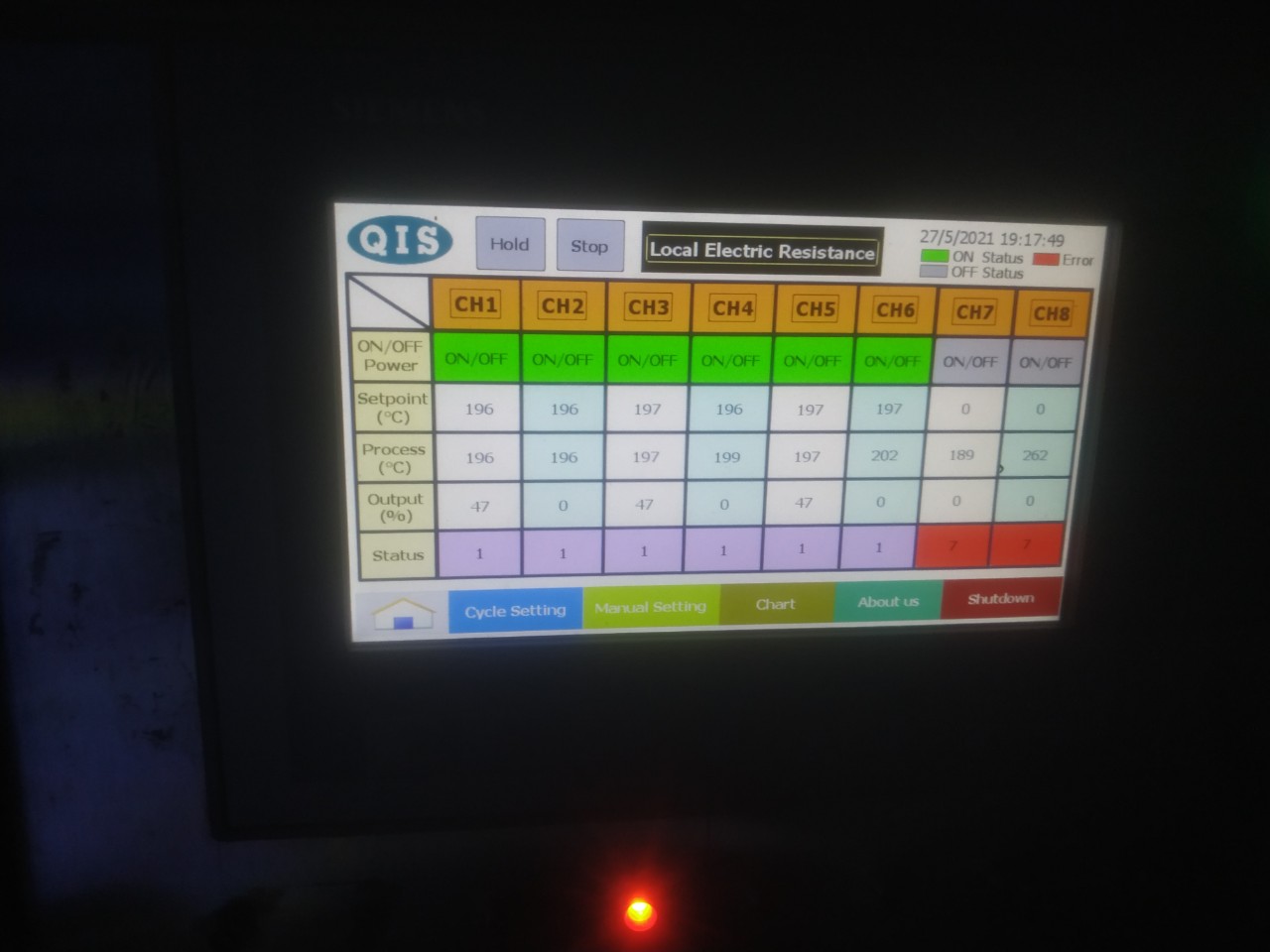

Nowadays, weld heaters are equipped with touch, display, temperature control systems that help to control weld heating to ensure welding quality.

Heat treatment process after welding

After welding, we must perform heat treatment for the following reasons:

- Eliminate residual stress. Residual stress after welding can cause brittleness, curvature, and deformation caused by the weld.

- For normalized steel or heat treated steel after welding, it helps to balance the mechanical properties of the connection’s different areas. Heat treatment after welding helps to ensure that the weld bond here is equivalent to the strength of the base metal, as well as meeting certain values for impact toughness.

- For coarse grain structure in steel that occurs during processes such as electro-slag welding that may require post weld normalization, post weld heat treatment helps to smooth the grain structure, eliminate stress and heat-affected regions.

- For some hard alloys such as aluminum alloys after welding PWHT (organization annealing and aging) helps to restore the metal’s properties as before welding.

QIS Non-Destructive Testing Services Co., Ltd was established in 2000, with more than 20 years of experience, in an effort to maintain its leading position, QIS company’s management have invested a large budget to research, invest, improve and build advanced, environment-friendly technologies.

Based on that strategic orientation, the R&D department was born including a team of rigorously selected leading engineers and doctors, to the most advanced machines and equipment... to serve the research, development, developing, creating and improving new products, applying optimal processes to production, assembly and operation activities, ensure high applicability, improve the product’s quality, current services with the better prices to target long-term goals and strategies.

QIS has performed PWHT services for many projects, onshore and offshore in oil & gas industry, power plant, gas, refinery and marine industry in particular as well as industry in general. QIS has been highly appreciated by supervisors and investors for its capacity and working results, along with a team of skilled technicians with many years of experience, the flexible management system, advanced & quality equipment have contributed the trust, satisfaction of customers and QIS’s brand.

Some typical large projects: East Sea 1, Long Son Petrochemical Complex (A1, A2, B & C, ...), Sapura, Dos Bocas New Refinery...

Prestigious partners: PTSC M&C, PV Shipyard, PVC MS, PVD Tech, VGCE, AMECC, POSCO E&C…

Qis Ndt

#QIS #GWEC #ndt #inspection #mechanicalcompletion #advancedndt #pwht #renewable #energy #membership

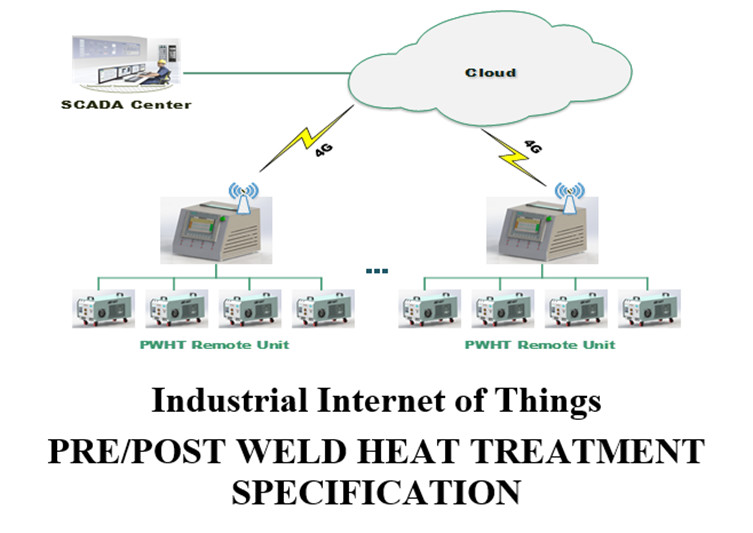

The research and manufacture of new products PWHT with Internet of things is carried out by the leading engineers and doctors team in QIS's R&D department.

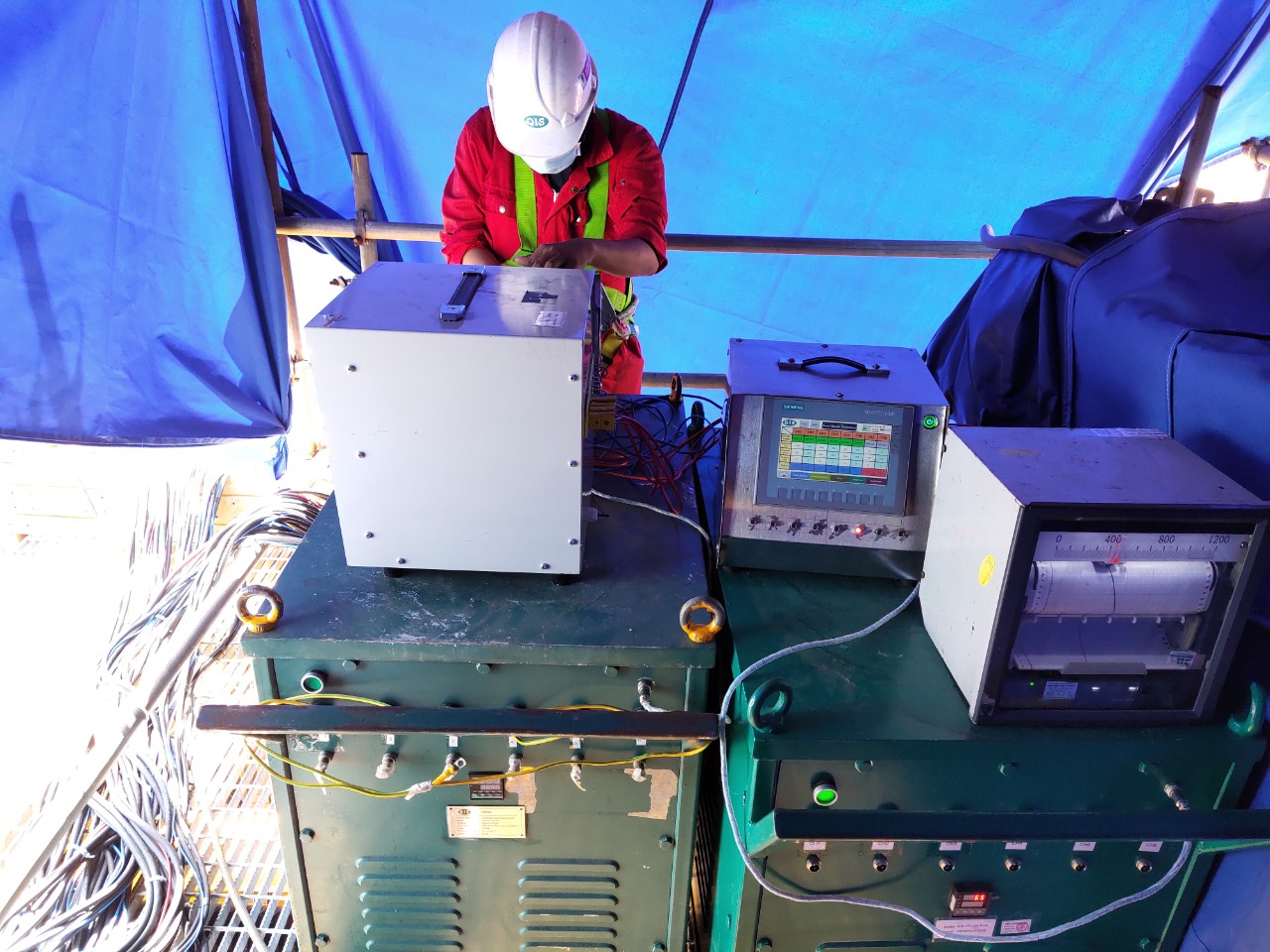

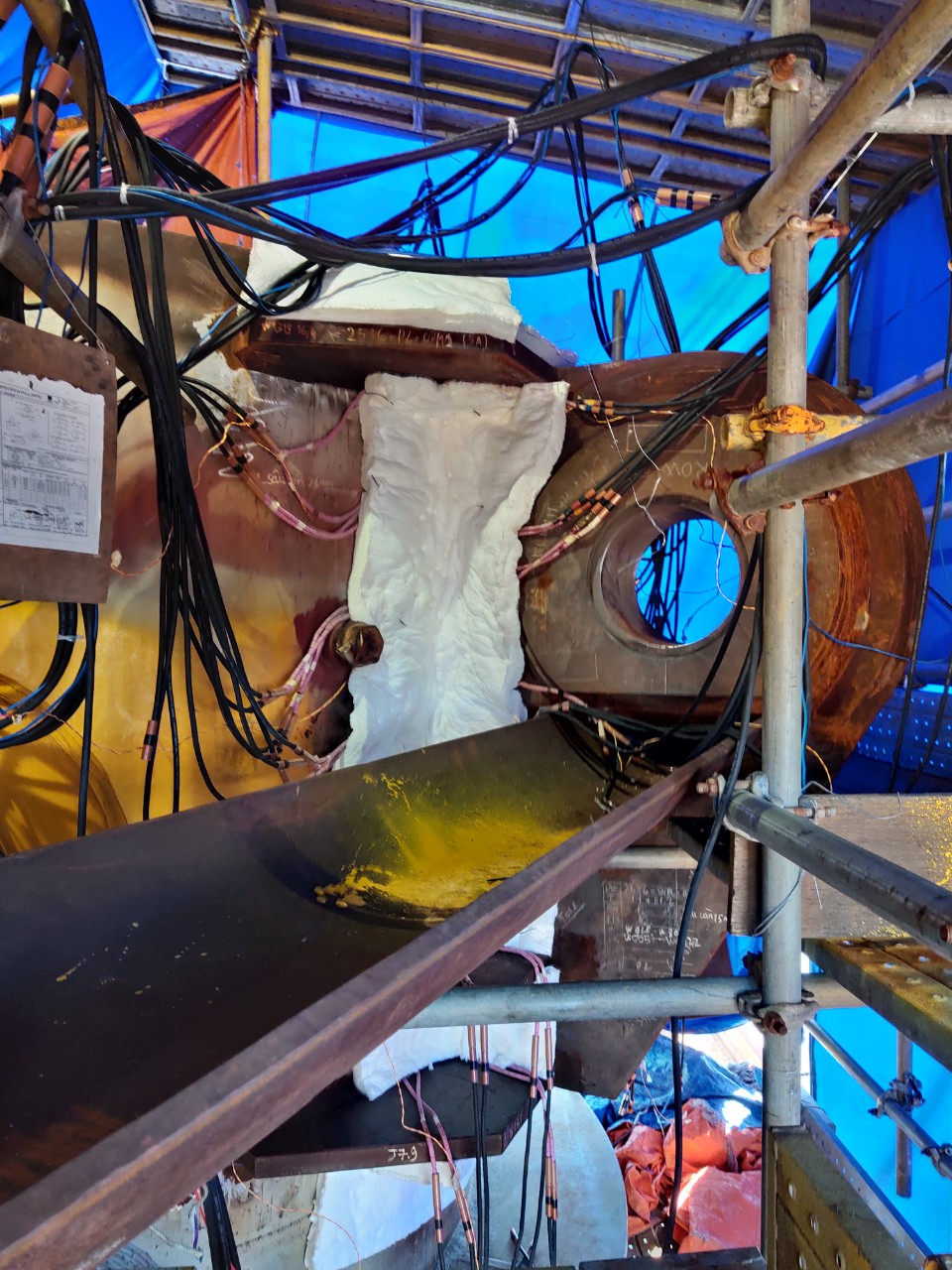

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.

Some typical images of QIS's PWHT service.