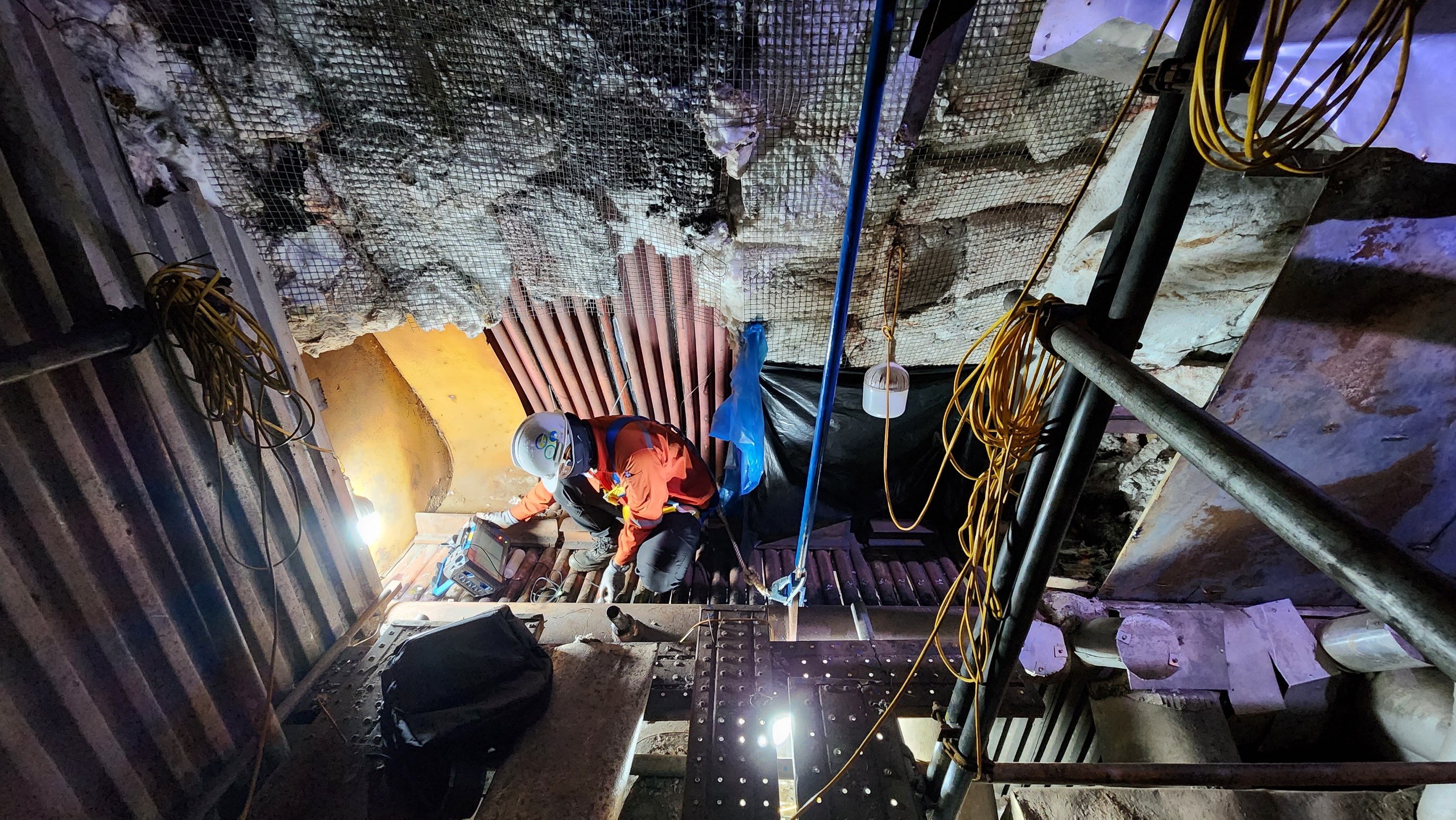

The Project Management Division of QIS had just gone through a challenging week to complete the task of handling the welding defect at the four corners of furnace 1's cold flue tube after the overhaul for PV Power, PV Power Hà Tĩnh, and Vung Ang 1 Thermal Power Plant.

The task demanded a high level of difficulty and precision, leading QIS to assign a 15-year experienced specialist to consult on identifying the cause, repair solutions, and handling the leakage issue at the nozzle weld position. Additionally, they conducted PAUT to determine the length of the nozzle tube, identify the defects in the nozzle weld, and Inspection of the microstructure using replica for the boiler tube array...

"Every beginning is difficult," Hà Tĩnh welcomed the QIS experts with a fairly heavy storm, making the process of transportation and work more challenging than ever. Nevertheless, nothing could deter the determined spirit of the QIS team. They had to exert themselves day and night, subsisting on simple quick meals to keep up with the project schedule. Ultimately, the QIS experts successfully completed the project with trust and high regard from the client.